Based on the heavy traffic on the current asphalt road, irregular cracks of varying degrees will appear after the first winter; Irregular cracks will also appear when the original road surface is widened, and when the subbase quality is not good enough.

Our technicians have repeatedly tested the cracks in the asphalt pavement and developed a high-quality asphalt pavement sealant. The product has strong adhesion, high temperature non-stick wheels, low temperature non-brittleness, anti-aging and other characteristics, our hot melt crack sealant quality has been recognized by worldwide road maintenance and construction companies approval.

Advantages:

Economical and practical, high quality and low price, high cost performance;

Adapt to temperature -30℃ to 60℃, no flow at high temperature, no sticking to wheels, no brittleness at low temperature;

It has extremely strong adhesion, guarantees good adhesion to the road contact surface.

Good elasticity, large amount of stretch, can withstand large displacement.

Excellent construction performance, after the material is heated, the viscosity is small, and the pouring is dense;

Construction:

Preparation: Put the safety signs in place, put the slotting machine and the joint filling machine in place; prepare slotting according to the construction requirements, start the joint filling machine to preheat, add crack sealant and stir, control the temperature between 170℃ and 200℃.

Grooving: Install a suitable saw blade according to the size required by the construction (recommended width and depth are both 13cm-26cm), adjust the required depth, and perform slotting operations.

Clean up: After manual cleaning, use an air compressor or a knapsack blower to thoroughly clean up the debris and dust in the seam.

Filling joints: When the crack sealant temperature is between 170℃ and 200℃, start to fill the joints; the temperature of the joints is recommended to be above 10℃; if the temperature in winter is below 5℃, it is best to preheat the part of the groove before starting to fill the joints.

Maintenance: After 15-30 minutes of filling, the traffic can be opened.

(ASTMD6690-2007)《Test methods for hot melt crack sealant for joints and cracks in asphalt and Portland cement concrete pavements》、(JT/T740-2009)《Pavement rubber asphalt grouting glue》。

| Testing Item | Unit | Testing Result | Result | Testing Method |

| Asphalt Compatibility | — | Pass | Pass | ASTMD5329-2007 |

| Penetration (25℃,0.1mm) | 0.1mm | 36 | 30-70 | JT/T740-2009 |

| Elastic Recovery (25℃,%) | % | 54 | 30-70 | JT/T740-2009 |

| Liquidity (60℃,mm) | mm | 4.0 | ≤5 | JT/T740-2009 |

| Adhesion tensile test: 20 degrees tensile 50% 3 cycles passed | ||||

Application:

Maintenance and sealing of cracks on asphalt pavement;

Treatment of cracks on old asphalt pavement before paving the asphalt wearing course, and treatment of sub-base cracks of asphalt concrete pavement on cement concrete pavement;

Treatment of bridge head jumping and expansion joints; sealing of reservoir embankment joints

Treatment of the joints between the airport runway and the cement concrete plate;

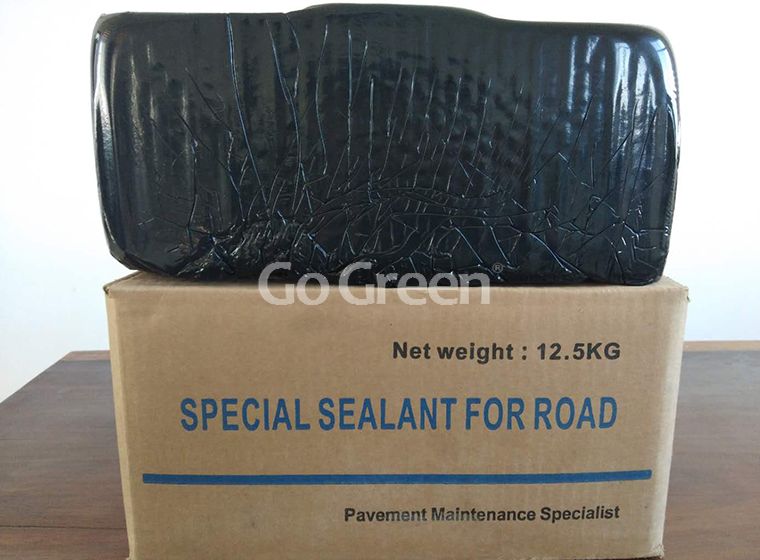

12.5kg per box, 80 boxes on a pallet

Shelf life unopen: 1 year