Go Green Micro Paving Warm Mix Asphalt is a new type eco-friendly warm mix asphalt wearing course material, mainly used for high grade pavement preventive maintenance and slightly pavement distress corrective maintenance, it can also used for paving new road, which has anti-skid, reduce noise, anti-fogging and environmental friendly features, at the same time, it can effectively improve the road evenness. Paving thickness is 0.7-1.5cm, typical thickness is 1.0cm.

Micro paving warm mix asphalt emulsion asphalt aggregate mixing ratio is 6%, which means to produce one ton warm mix asphalt finished materials only require 57kg emulsion, typical paving area is 42m².

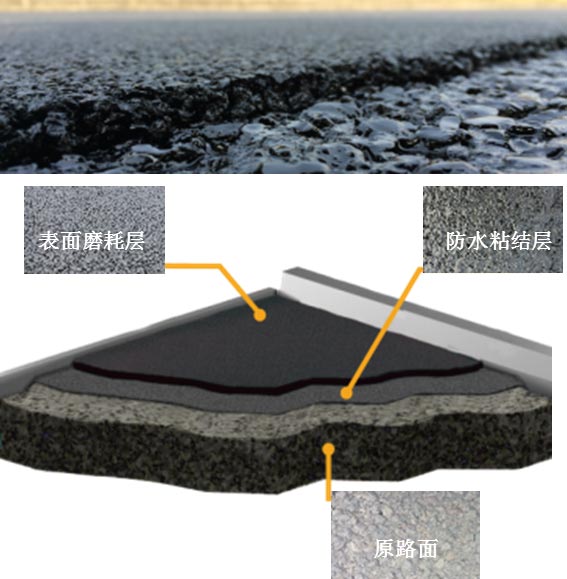

Warm mix asphalt micro overlay consist of surface micro overlay and waterproof adhesive layer, the surface is anti-skid wearing course, adopt warm mix technology and specialized modified bitumen and OGFC-5 gradation; Waterproof adhesive layer adopt the modified bitumen, which can ensure bonding well between the original pavement and micro overlay, and form into the waterproofing layer, effectively prevent the rainwater infiltration.

Go Green Micro Paving Warm Mix Asphalt Advantages:

1. Build new surface layer, prolong the road service time

Waterproof adhesive layer has good penetration and bonding effect, it can provide a good bonding effect between the old road and the surface layer while plugging the small cracks on the old surface. Moreover, it can effectively prevent the spalling of the thin surface layer. The asphalt mixture has good pressure sensitive property, more heavy traffic volume passing by, the stronger adhesion will be formed between micro surface and the original road.

2. Improve the road evenness, repair slight ruts

3. Improve road anti-skid performance

Warm mix asphalt micro overlay has good skid resistance, which can effectively improve the adhesion of tires in rainy days and reduce the occurrence of traffic accidents.

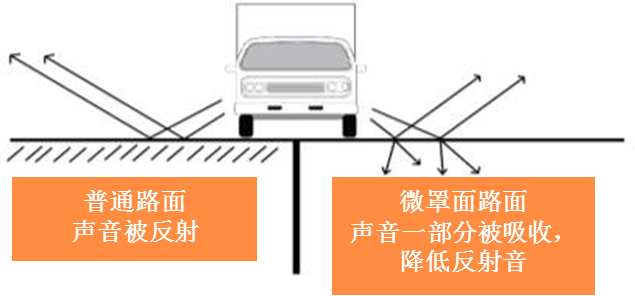

4. Reduce noise, improve driving comfort

Micro overlay adopt the OGFC-5 structure, the voidage can reach 12%, effectively reduce the noise caused by the air squeezing and the pump suction when the tire is running on the road, and improve the comfort of the driver.

5. Form road surface diffuse reflection, improve driving safety

The surface of the micro-cover is rough and easy to form diffuse reflection, which effectively prevents the reflection phenomenon, thus greatly reducing the road traffic accidents. Pavement voidage is 12%, rainwater can infiltrates into the micro-cover layer, no hydrops on the road surface, thus to reduce the water mist and improving the driving safety in rainy days.

6. Reduce the road maintenance cost

Only require warm mix in asphalt plant, greatly save the energy, considering the materials ultra thin feature, it can effectively save project maintenance cost.

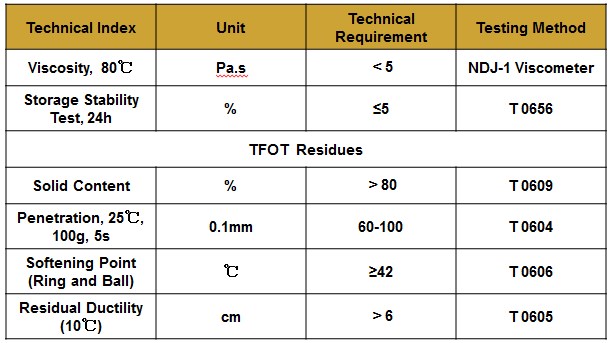

Go Green micro paving warm mix asphalt technical index

Go Green micro paving warm mix asphalt application range: high-volume expressway, highway, county roads, city street, tunnel driveway, elevated driveway, airport runways & bridge installations

Production: during manufacturing, it should adjust the feeding materials ratio and speed, mixing time is about 50 seconds, discharging temperature should be control at 80~135℃

Temperature Control:

1. Aggregate heating temperature: 120℃~130℃

2. Micro paving warm mix asphalt emulsion heating temperature: 80℃~100℃

3. Materials discharging temperature: 80℃~135℃

Materials Transportation:

1. Ensure the truck is clean, no big asphalt granule

2. Spray some oil at the truck bottom and side panel as the isolation, the oil should not be soluted with asphalt

3. Truck should be covered with waterproof cloth to prevent dust and keep warm

Treatment before Construction: Close the traffic, clean the paving area

Spraying tar coat: dosage is 0.2-0.3L/m², to ensure its good effect, it should be spraying tar coat ahead of 30-90 minutes before paving the warm mix asphalt, at the same time, ensure the pavement is clean out of pollution

Paving: warm mix asphalt materials should be paved uniformly on the surface with tar coat, paving temperature is above 80℃

Compaction: using steel wheel compactor to compact the pavement, the thickness should be 1cm, suggest to use 4~8 tons light weight compactor, compacting 2-3 times, and the compacting temperature should be above 60℃

Accept Traffic: when the surface temperature cool down to below 30℃, it can open to traffic, generally about 3 hours.

Go Green micro paving warm mix asphalt emulsion package: 200kg drums

| Package Name | Photo | Description | Container Loading |

| Micro Paving Warm Mix Asphalt Emulsion |  | Go Green micro paving warm mix asphalt emulsion is used to produce warm mix asphalt materials, asphalt aggregate mixing ratio is 6%, to produce one ton finished materials only require 57kg emulsion | 200kg drum, net emulsion weight is 180kg, 4 drums per pallet |